Beyond Material Optimizations

Intro

Working within the realm of structural engineering, my experience as a computational designer has often led to explorations around materials and energy. A significant portion of this has been dedicated to grappling with embodied carbon data for structural materials (primarily steel and concrete). Despite the messiness of this data, there’s a growing awareness of the carbon impact of building materials, and increased efforts across the industry to try and better track material impacts. I think it’s an important topic that is worthy of the time that many industry experts have been spending on it, but it’s very easy to get lost in the weeds.

By taking even a small step back, it becomes apparent that we spend a lot of time optimizing fundamentally flawed approaches to construction methods when viewed through the lens of energy. Since embodied carbon data for building products is often explained as “nutritional facts for building materials”, I’ll stick with a food-themed analogy. If my goal was to eat a healthy snack, I could spend a lot of time trying to make a low-fat cookie that is bound to taste worse than its buttery counterpart. Alternatively, I could just have a piece of fruit or some nuts. Recently, one of the main areas of focus of the industry regarding embodied carbon has been around optimizing concrete mixes, which is akin to the low-fat cookie approach. While this is an effective approach on reducing embodied carbon, and should continue to be pursued, there are potentially more impactful improvements to be realized by switching systems (snacks) altogether.

One of the big reasons we tend to focus on mix design as opposed to finding alternative systems and materials is that it’s a relatively achievable improvement that faces minimal friction from contractors. Whether a particular concrete mix has a low Global Warming Potential (GWP) or not tends to have a relatively limited impact on the means and methods that a contractor will end up using during the construction process. In the carbon reduction game, this is essentially some of the lower hanging fruit low-fat cookies for architects and engineers to pick at without ruffling too many feathers and adding too much cost.

Focusing on Floors

Some of the leading proposals around reducing embodied carbon in building structures have been focused on floor systems. This is for good reason since these systems make up a significant proportion of the building mass in multi-story structures. Philippe Block and his research group at ETH Zurich have been looking at this for quite a while now and have been developing some novel alternatives that use significantly less material. According to Block, in mid-high rise construction you have roughly ¾ of the mass in the structure, more than half of which is in the floors. Furthermore, reducing the weight of the floor system has the added benefit of reducing the mass needed in the rest of the structure and foundations.

One of the primary reasons we often use the systems that we use has to do with the comfort level that designers and builders have with such systems. On the design side of things, commonly used flooring systems may be built into standard design guides, BIM libraries, and analysis software. This helps to streamline the design, analysis, and documentation of these systems. On the building side of things, there is always going to be a bias towards using systems that the contractors are familiar with in order to reduce risk and uncertainty in construction costs and schedules.

Case Studies

Before further discussing some of the current alternative flooring systems out there that offer improvements in terms of embodied carbon reductions, it’s worth looking at some historical examples. Specifically, I’ll look at some examples from the mid 19th to early 20th centuries. The reason for this is that many of the fireproofing concerns that we are required to address in current building codes were also being introduced during this period in response to a number of major fires across several American cities. It wouldn’t be until the early 20th century when reinforced concrete would become more ubiquitous, and so we see a handful of different materials being used in the construction of floor slabs such as brick, terra cotta, and cinder concrete. (I’ll highlight a couple examples below, but a more comprehensive overview can be found in this excellent article from Hoffman Architects.)

The value in looking at these systems is to demonstrate that creative and complex systems have been deployed en masse in the somewhat recent past, and can be again. These examples highlight a smart use of geometry and a more nuanced understanding and application of materials compared to many modern systems. While the demise of these historical precedents was largely due to their cost and complexity relative to advancements like reinforced concrete, it is worth reexamining them through the lens of embodied carbon. By doing so, we can identify strategies that emphasize material efficiency and apply materials in ways that leverage the strengths of their inherent properties.

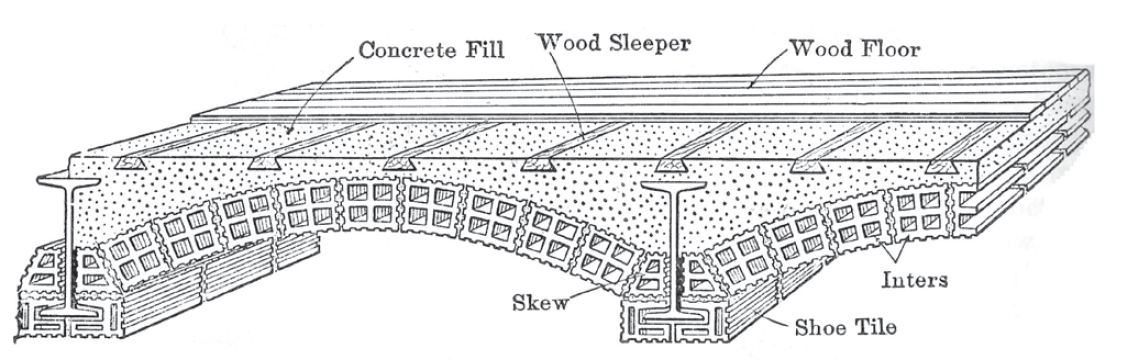

Clay Segmental Tile Arch System

Commonly used in warehouse buildings, the Clay Tile Arch system was often used in combination with steel framing, and would have a concrete topping applied. The clay tiles served both the structural purpose of transferring loads to the beams and also providing fire protection of the steel. There were primarily two types of arched floor systems: segmental (show above) and flat (shown below). This system would typically use tie rods between steel beams to resist the outward thrust from the arch. Cinder concrete was used as a lightweight fill material that was non-structural. While heavy and difficult to construct, they demonstrate a smart use of geometry at both the scale of the hollow clay tiles and the system overall.

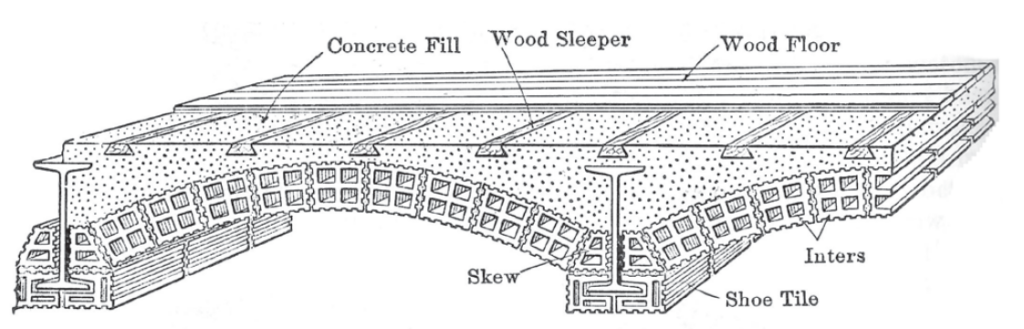

Clay Tile Flat Arch System

While not arch-shaped, the flat arch system functions as an arch with a tapered keystone at the middle of the span. Compared with its segmental counterpart, the flat system was geared more towards buildings where a flat ceiling may be desired, such as an office building. In these cases the clay tiles were often plastered-over on the underside. Similar to the segmental system, the flat clay tile arch would transfer loads to the adjacent steel beam via an outward thrust that was typically resisted with tie rods.

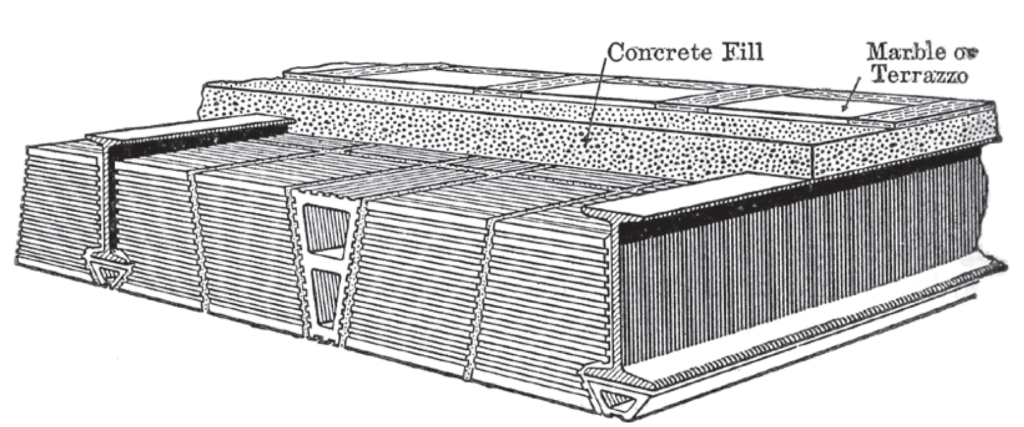

Roebling System A Type 2

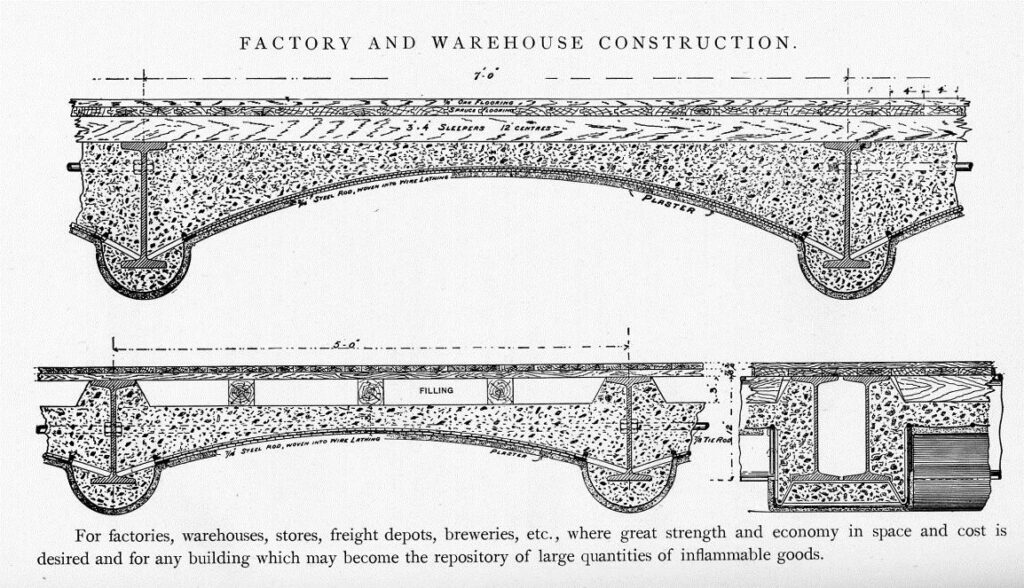

Around 1892, John A. Roebling’s Sons Co. introduced a couple of the first concrete flooring systems used in the US, which were designed to span between steel I-beams. The floor systems were marketed as lighter and cheaper alternatives to terra cotta tile and brick arches, which were the commonly used systems at the time. System A was an unreinforced concrete arch, and system B was a reinforced flat slab. System A Type 2 (shown above) was an economical option geared towards utilitarian purposes where the arches were exposed from below. This system consisted of cement concrete covering arched panels of stiffened wire cloth placed between I-beams. Above the concrete arch were wooden nailing sleepers with the gaps between them filled with a low-strength concrete, which were then covered with a wood finish floor.

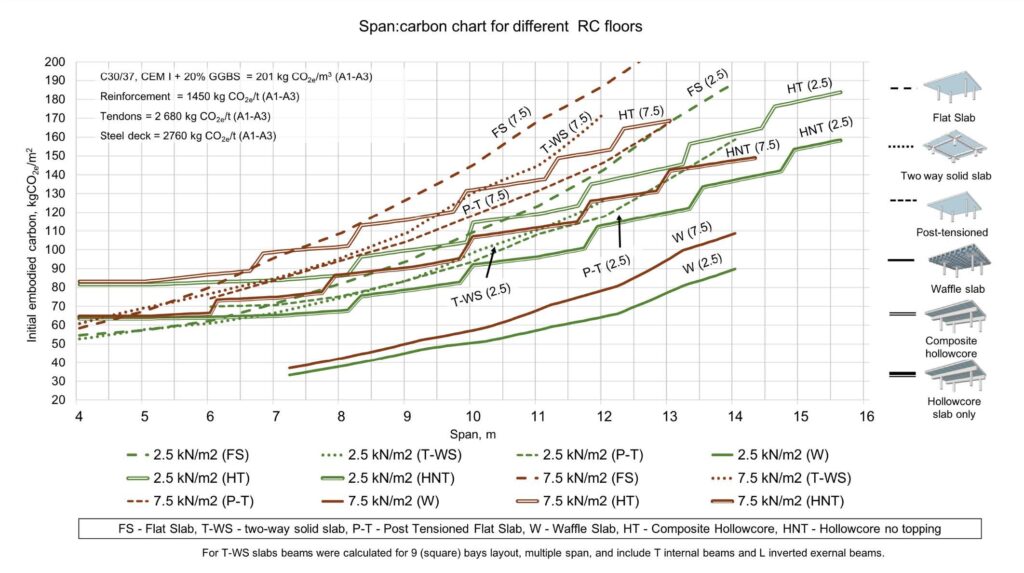

Modern Alternatives: Concrete + Geometry

Returning to modern day flooring systems, many of the most commonly used floor systems, like concrete flat slabs, are among the worst in terms of embodied carbon perspective. Concrete flat slab systems, commonly used in mid and high-rise structures, prioritize simplicity in design and construction over material efficiency. The opposite trade-off can be seen in a floor system such as a waffle slab, which effectively leverages geometry to reduce material, but has added complexity in its design and construction. A similar trade off can be seen with hollow-core slabs, which leverage geometry by removing material where it is not needed. While systems such as waffle slabs and hollow-core slabs have been around for many decades, they’re not often considered as a viable alternative in scenarios where something like a concrete flat slab would be applied. In addition to added complexity in the formwork, these systems often add depth, which means added overall costs. The reality is that in most cases simplicity and cost will win out over material effectiveness.

More novel approaches such as Philippe Block’s Rippman Floor System (RFS) further optimize their use of materials by following the forces so that they are placed only where needed. While potential applications for this system may be further limited by building typology, mechanical systems integration, and seismic concerns, they offer a creative solution that can provide aesthetic benefits in addition to their carbon reduction advantages.

Modern Alternatives: CLT/NLT Slabs

Another alternative flooring system that has been gaining more traction is cross-laminated timber (CLT) and nail-laminated timber (NLT) slabs. While these systems have been around for over 30 years, their implementation has been somewhat limited due to constraints such as cost, code compliance, and acoustical performance. However, we’re finally beginning to see growing availability of these systems as code acceptance and familiarity with their construction have grown.

During a recent site visit to a jobsite that was using a CLT slab system (this particular example was a hybrid system consisting of structural steel framing with CLT slabs), the project manager for the contractor mentioned that it was the first time that the particular crew on this job was installing a CLT slab system. The first bay took an entire day to install as they learned the system. The next day they installed 40 bays in a single day, and the install proceeded smoothly from there. He noted that they were now ahead of schedule, due largely to the CLT floor system going faster than anticipated.

While it’s still the case that CLT floors come at a cost premium compared to most concrete systems, that’s not inherently set in stone. Should more manufacturers enter the market, and more designers and contractors become familiar with the system, the costs of CLT systems will become more competitive over time. Additionally, the benefits of hybrid systems such as steel frame and CLT slabs are becoming more apparent – with these hybrids, designers can get the benefits of relatively shallow depth steel framing members (when compared to timber frames) with the lighter CLT floor systems (when compared to concrete slabs).

Conclusion

While much of the discussion around embodied carbon in buildings has focused on Environmental Product Declarations (EPDs), which help to put pressure on product manufacturers to provide lower impact solutions, we also need to give more attention to some of the bigger picture strategies that precede material optimizations. I’ve used floor systems as an example here since I believe it to be one of the areas with the biggest opportunities for impact, but the same thinking can be applied to other areas of buildings.

It’s easy to throw your hands up and say the market forces dictate everything in construction, and therefor we can’t do anything about it. While it’s mostly true that construction methods using less material will be less costly, and therefore market forces and embodied carbon reductions are already aligned, there is still often room for improvements. The incentives to reduce materials such as concrete are not often very high due to the relatively low cost of the material. Efforts to change our current practices are often dismissed due to their complexity. That said, the building industry often confuses complexity with a lack of familiarity.

If we were to look at familiar floor systems like flat slabs or composite decks, there’s typically a huge mess of steel reinforcement and multiple trades required to come on site for each floor that’s poured. It’s a very messy process, but since we’ve become so accustomed to it, it’s highly predictable and perceived as relatively simple. Should contractors become more familiar with lower impact floor systems, coupled with creative solutions to reduce and reuse formwork (in the case of concrete systems), it’s not all that hard to imagine alternative floor systems being able to reduce costs to a point where they become a more competitive option.

As anyone in the AEC industry knows, for any given project there’s a very complicated web of factors that need to be balanced, and so simply swapping one building system with another is not a trivial thing to propose. I’ve barely touched on potential concerns related to building codes, seismic, material supply chains, and various other factors that would influence such a decision. That said, while these concerns may eliminate certain options in certain regions, there are likely more impactful improvements that can be made beyond optimizing concrete mixes on systems that are inherently far from optimal from a material-use perspective.